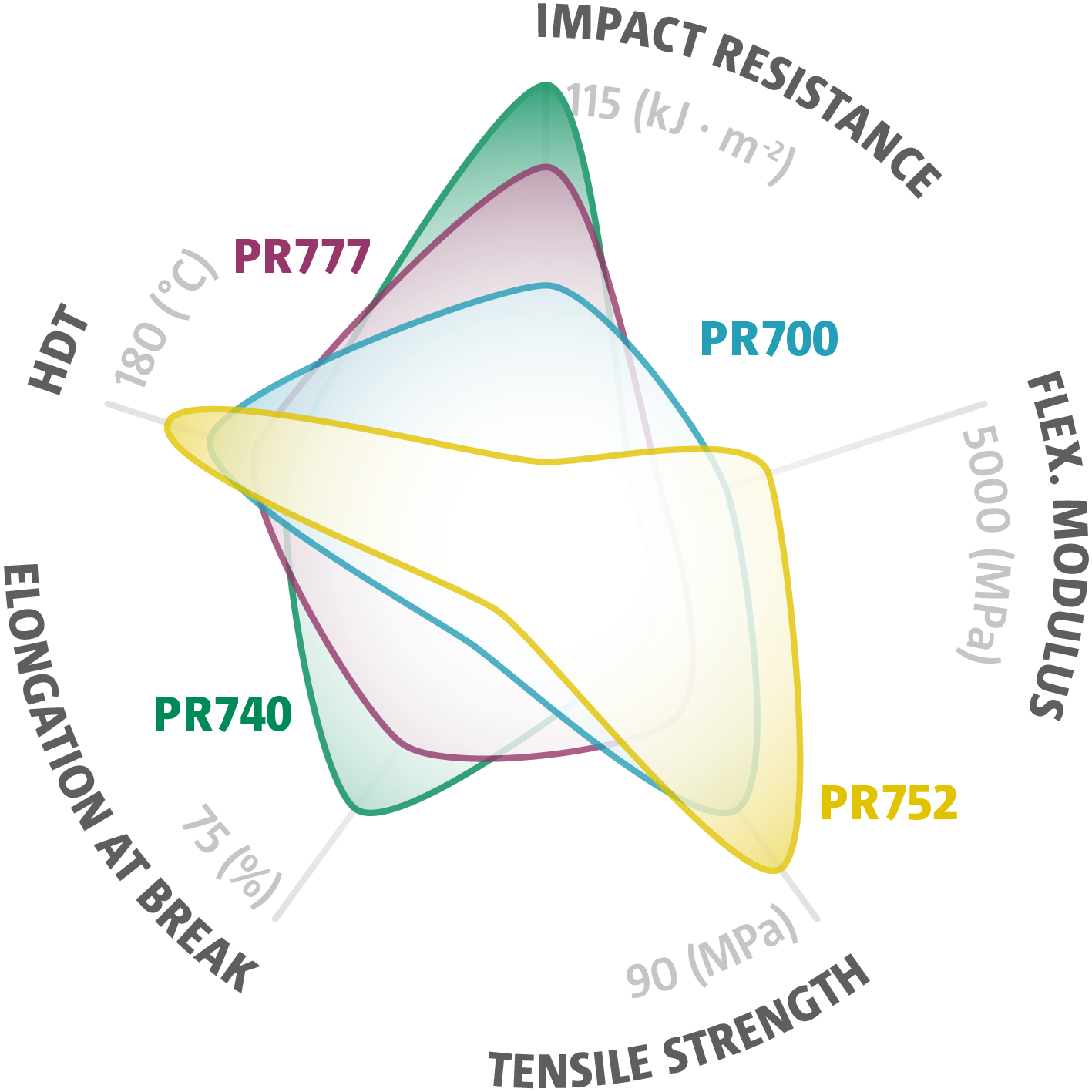

SYNTHENE’S Line OF PRODUCTS Gathering performance & simplicity

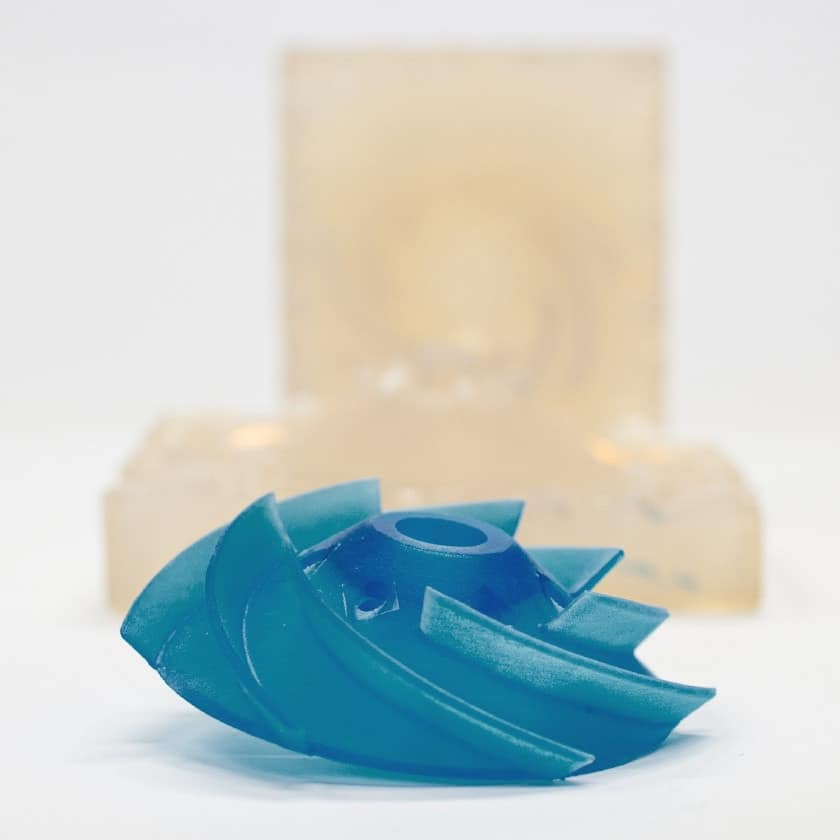

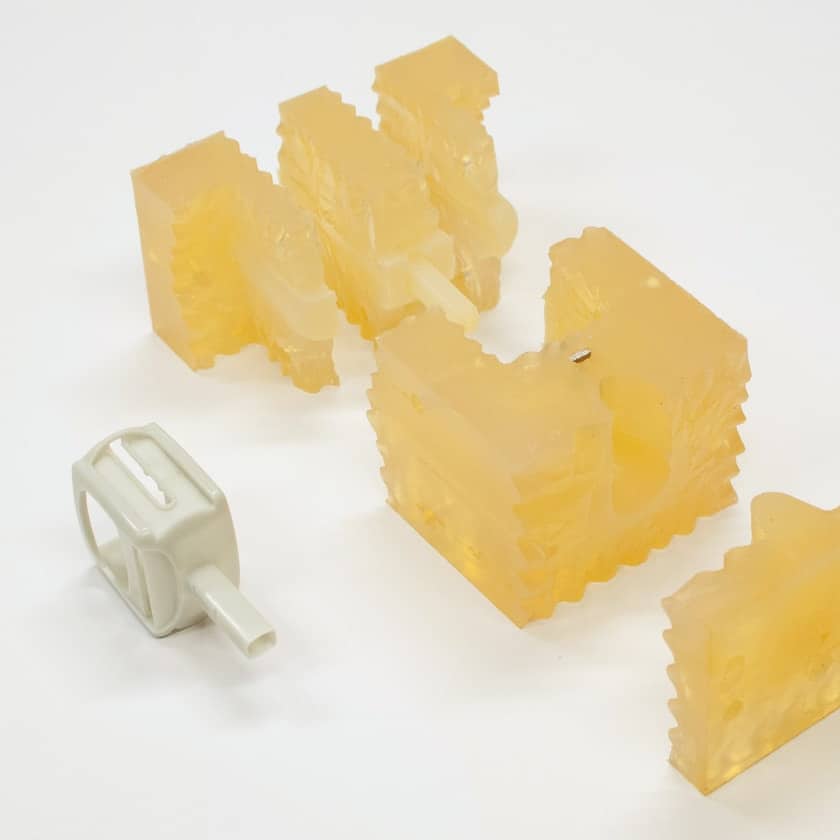

- Based on the technological assets of PR700

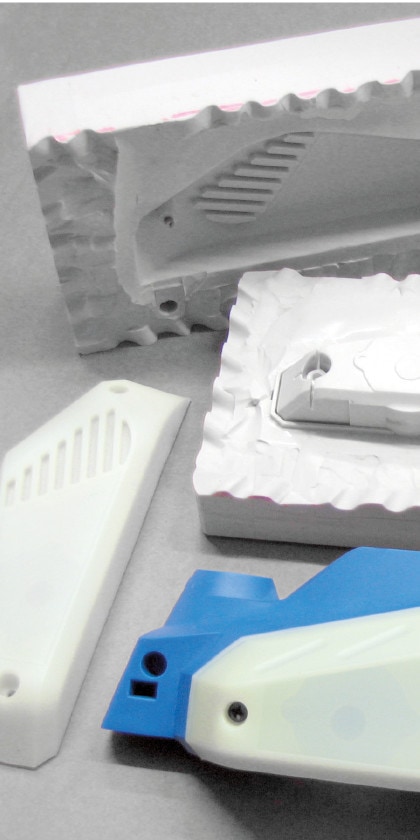

- Available in versatile rigidities & colourabilities

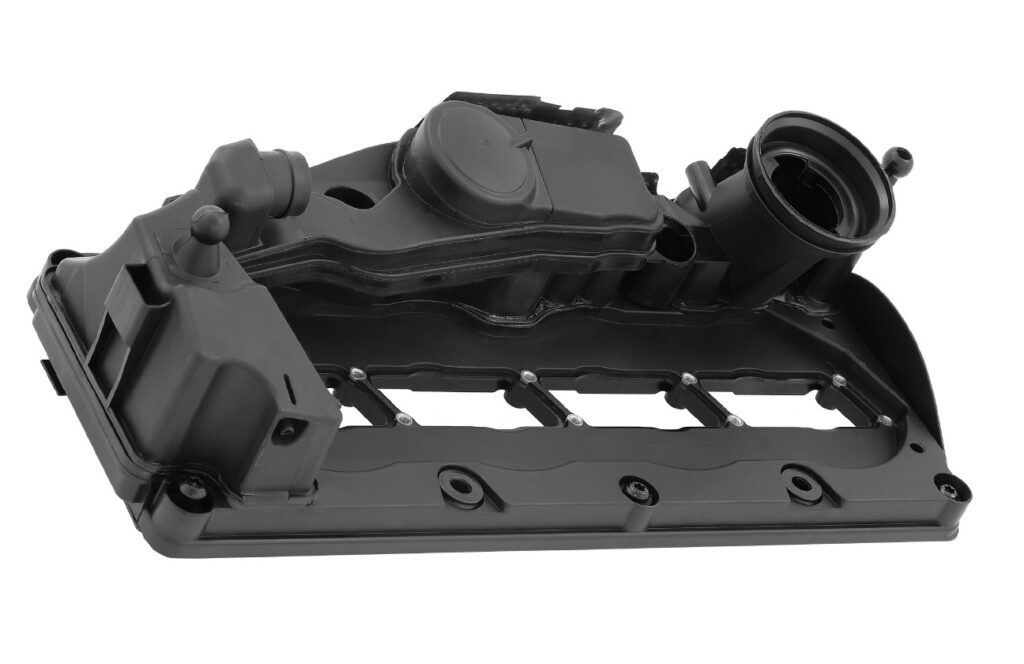

- For the simulation of thermoplastics like HDPE, PP & ABS

- The common technology of the PR7 SERIES is based on the PR700 isocyanate that is

- also used for PR752, PR777 and PR740

- For that reason, all those resins share PR700’s low-aggressiveness to silicone moulds

- They also offer an easier storage as they benefit from a long shelf life of 18 months and a common single component

In Accordance With

EC Regulation 1907/ 2006, SVHC list in force

Directive EU 2011/ 65, 2015/ 863 & 2017/ 2102

2000/ 53/ EC

2002/ 96/ EC

2000/ 11/ EC

IMDS (mdsystem.com)

AT A GLANCE

Documents

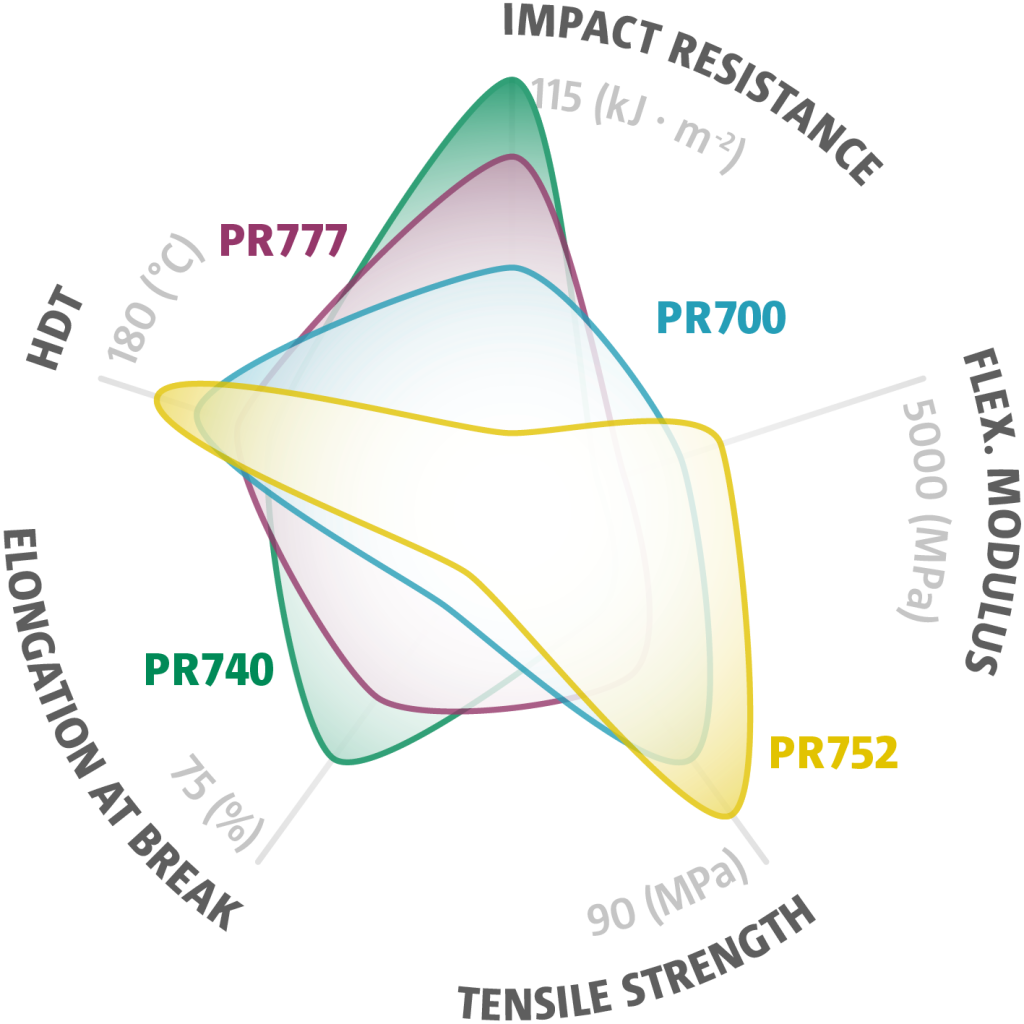

Flyer PR7 SERIES

Flyer presenting the whole PR7 SERIES range. Highlight and Comparison of the advanced properties of the PR7 SERIES.