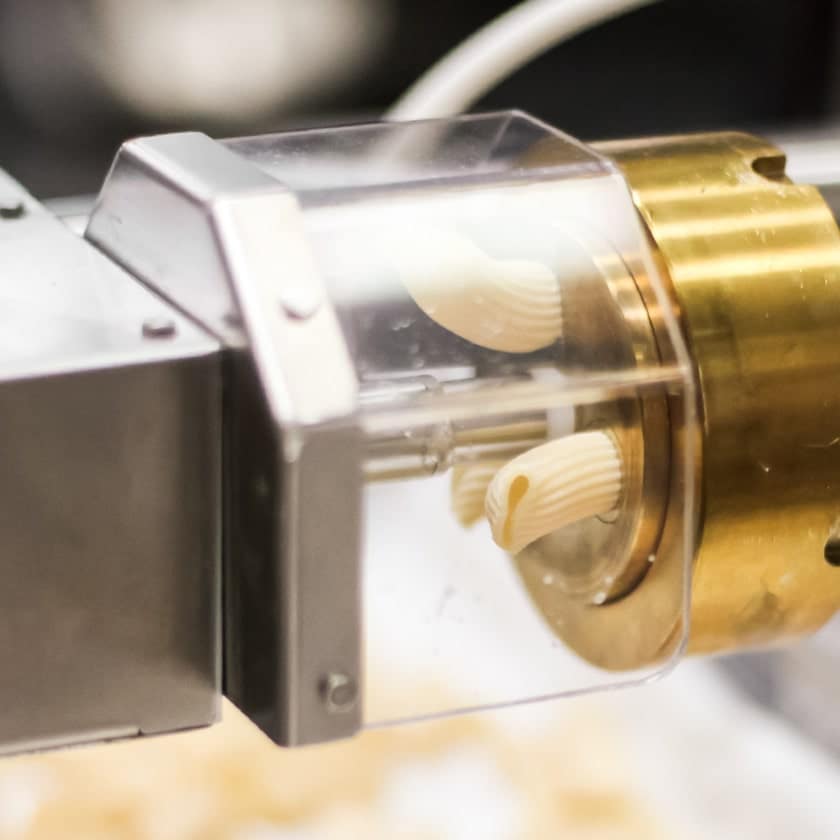

FOODGRADE POLYURETHANE RESIN

- Fully tested and certified

- Clear, transparent and colorable

- For prototypes and industrial parts

space

- Suitable for various types of food: dry, greasy and humid aliments as well as clear, cloudy and alcoholic beverages

- For temporary, repeated and long contact

space

- Food compliance is associated with superior transparency to offer a highly singular material

- This great clarity also presents a neutral basis for color researching

space

- PRF100’s characteristics have convinced food-processing and pharmaceutical industries

- The raw materials have been carefully selected to meet the requirements of food contact guaranty

space

- Like the FDA, a compliance to the 10/ 2011 EU regulation involves a mandatory migration test to ensure a complete safety management

- The compliance of the PRF100 with EU regulations has been analyzed and validated by an institute specialized in Quality, Health, Safety and Environment

In Accordance With

EC Regulation 1907/ 2006

Directive EU 2011/ 65, 2015/ 863 & 2017/ 2102

2000/ 53/ EC

2002/ 96/ EC

2000/ 11/ EC

Documents

Flyer PRF100 RESIN

Flyer presenting the benefits and technical information about the PRF100.

TDS PRF100

Technical data sheet of the PRF100. All mechanical and thermal properties of the innovative food-contact transparent resin PRF100.

- chemical resistance

- dielectric properties

Truly foodgrade

Safe for dry Foods ⁴

Cereals, flour, dry pasta, biscuits, dry fruits, herbs, spices, pills etc.

Safe for clear beverages ⁴

Water, clear fruit juice, lemonade, soft drinks, syrup etc.

Safe for Fats ⁴

Olive oil, meat, fish, seafood, eggs, chocolate, cheese, seasoning in oily medium etc.

Safe for cloudy drinks ⁴

Liquid chocolate, beverages containing pulp like juices, nectars and soft drinks etc.

Safe for Fresh Foods ⁴

Fresh fruits and vegetables, unpeeled, peeled or cut etc.

Safe for Alcoholic drinks ⁴

Alcoholic beverages of an alcoholic strength up to 50 % vol., liqueurs containing cream etc.