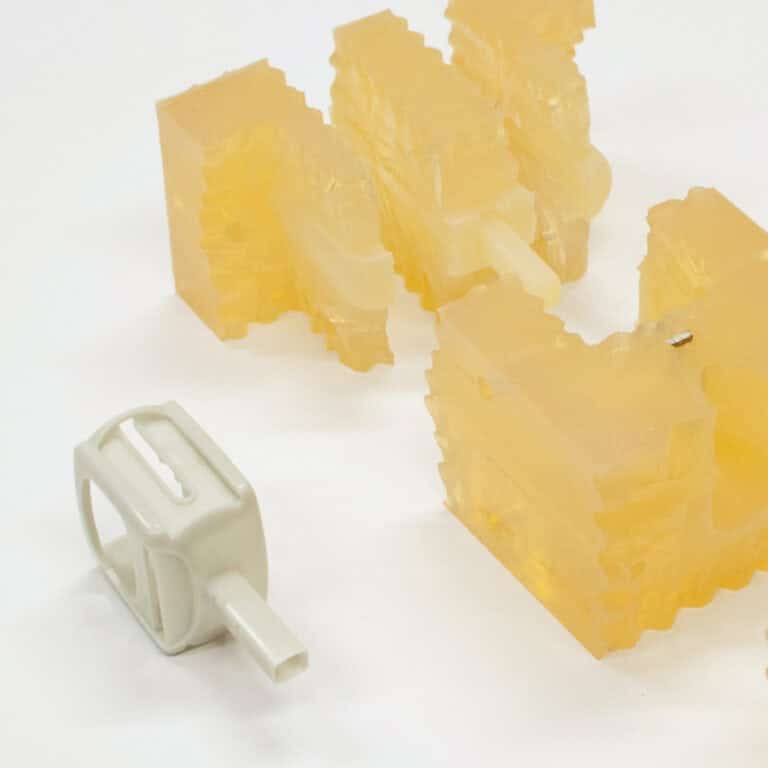

FOCUS PR7 SERIES unique performance, exceptional mould life

for semi-rigid and rigid

- Simulation of PP, HDPE and ABS with high temperature resistance

- Exceptional chemical resistance to be used in engine environment

- High mechanical strength for durable parts

- Combining long potlife with short demoulding time for more user-friendliness

The PR777, PR740, PR700 and PR752 resins share the same isocyanate, PR7 SERIES ISO. This material has been particularly formulated by Synthene’s R&D laboratory to be extremely gentle on silicone moulds.

The PR700 is SYNTHENE’s worldwide best-seller due to its high-end overall properties, used in many industries. For automotive projects, it is the preferred choice for both prototyping and small series.

Most of the PR7 SERIES materials can also be reinforced with the SYNFILL G glass fiber filler, allowing the resins to go up to a 4650 MPa modulus and a 177°C HDT.

Polyurethane expertise in PU, from design to production.

- A large catalogue of efficient vacuum casting resins for prototyping and small series like automotive and consumer electronic projects

- High performance elastomers for demanding industrial applications as oil & gas, aerospace and medical

- Long-lasting moulding and coating materials for construction like concrete moulds for decorative stones

- User-friendly and UV-stable solutions for design and art applications like river tables

Polyurethane is a thermosetting polymer composed of polyol and isocyanate. PU resins come in a variety of application processes and especially gravity casting that is mostly used to transform SYNTHENE products. The two components are mixed together in a liquid state and then casted. The chemical reaction creates a solid and durable plastic material. SYNTHENE formulates polyurethane going form the softest elastomers to the toughest resins.

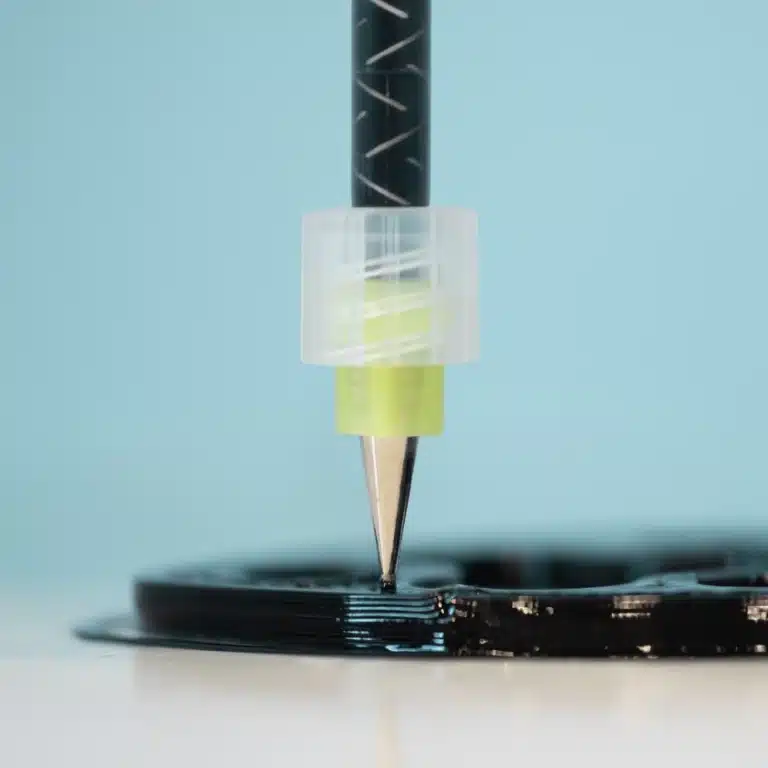

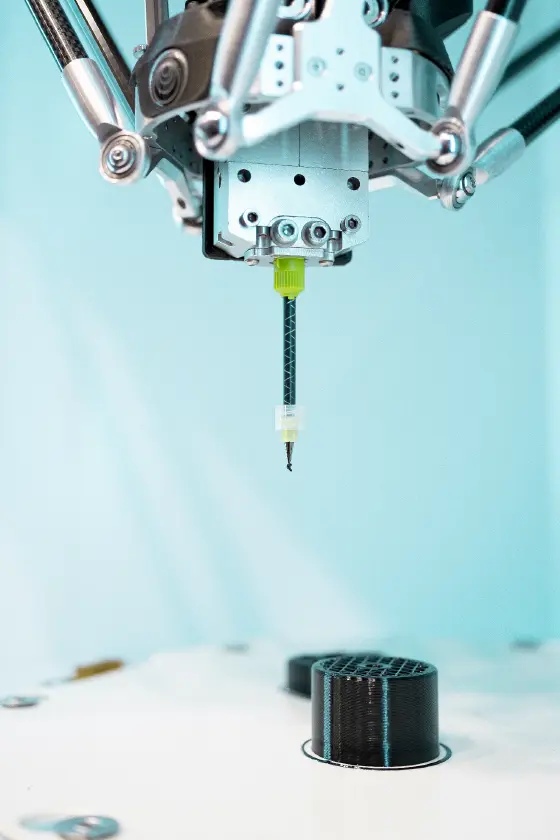

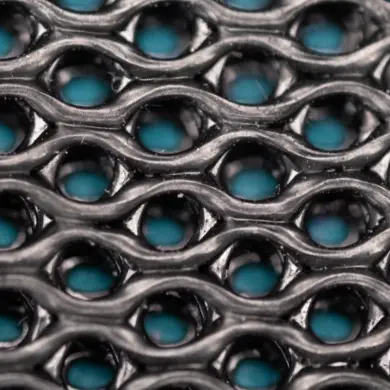

New PUprint – SYNTHЭD+ revolution in 3D printing

- Print unique shapes without the constraints imposed by the moulding process

- As tough as vacuum casting PUs

- From soft to semi-rigid with four different hardness levels available

- High mechanical and thermal resistance

PUprint is the first system to be launched in the SYNTHЭD+ range which will be dedicated to additive manufacturing.

SYNTHENE’s mindset is to bring high performance to the 3D printing industry for fully functional parts that are as resistant as conventional parts.

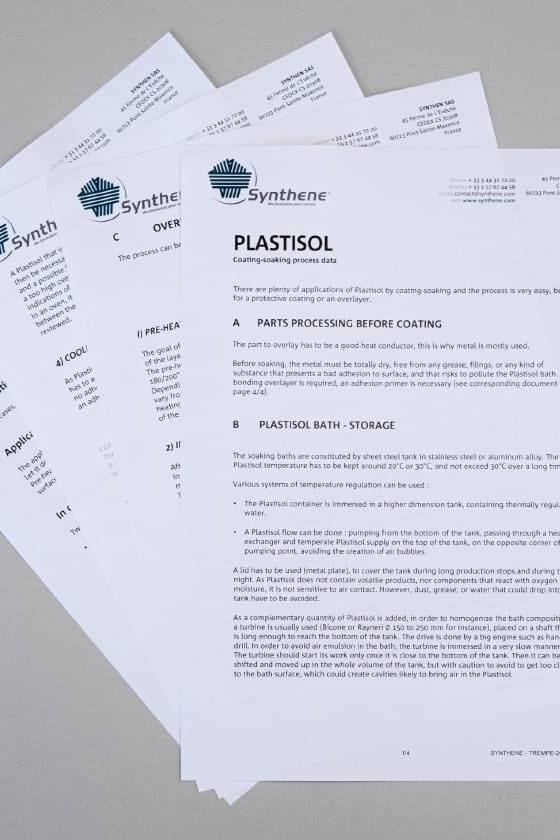

PLASTISOL a wide scope of personalised solutions.

- Adjustable hardness, viscosity, rheology, colour and aspect

- Specific formula development, respecting the design brief with specific standards like toy regulations, flame retardancy, electric insulation etc.

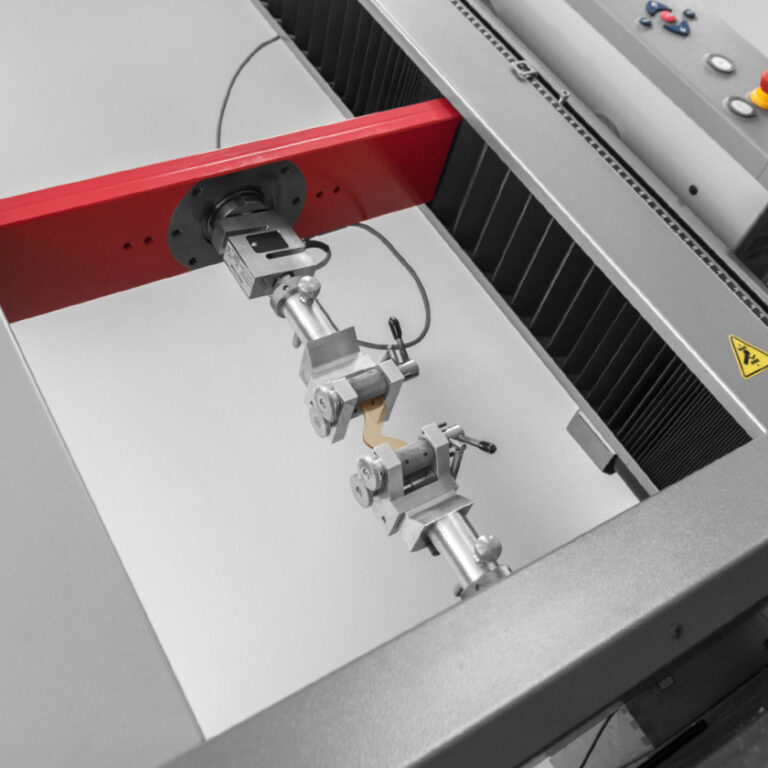

- Excellence in dipping, coating, slush-moulding, rotomoulding etc.

Plastisol is a paste obtained by the dispersion of a PVC powder resin into a liquid plasticizer. After a thermal treatment, the product results in an elastomer.

SYNTHENE has been formulating Plastisols on demand since the 1960’s, following precise lists of specifications.

FORMULATION high-performance tailor-made solutions.

- SYNTHENE is above all a dedicated R&D laboratory elaborating precise formulas to build up innovative projects

- Expertise joins safety awareness to tackle the industrial challenges of tomorrow

- Customer service is at the heart of SYNTHENE’s approach to offer a consitent follow-up

SYNTHENE formulates custom solutions for polyurethane, PLASTISOL, detergent etc.

SYNTHENE’s team studies the application projects and provides support to optimise their development. This is done either by giving recommendations on existing products, or by opening a new file by the R&D laboratory.

support customer service in a few clicks.

- SYNTHENE’s hotline and support email address where a competent member of the team will help you

- All documents and guides available for SYNTHENE’s wide line-up of products

About SYNTHENE start-up spirit since 1958.

SYNTHENE places a particular emphasis on offering high-performance products, with cautiously selected raw materials from trustworthy manufacturers. All SYNTHENE prototyping resins meet the current requirements of REACH.

SYNTHENE is

certified according to