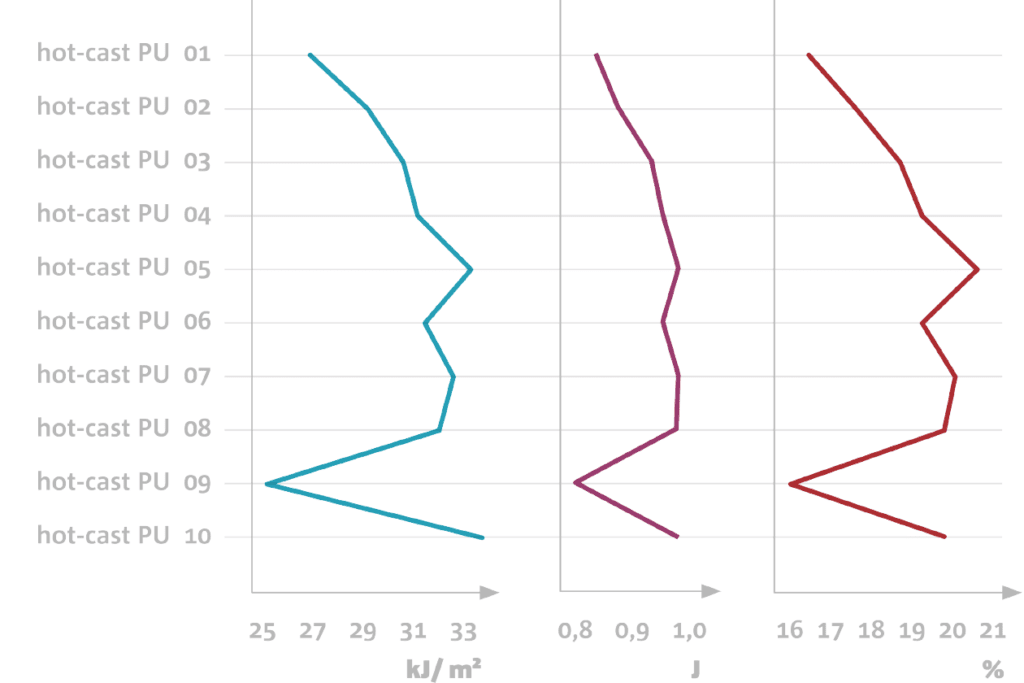

Remarkable TEAR RESISTANCE

- Even notched, SYNTHENE hot cast PU still offers a high tear resistance to keep facing the targeted challenges

- Repeated tests in various conditions ensure that the materials grant the required properties

- Typical applications are bellows, skateboard wheels, shoe soles etc.

Documents

Video Clip about Tear resistance

A short video clip showcasing SYNTHENE’s test procedures to ensure the required tear resistance.

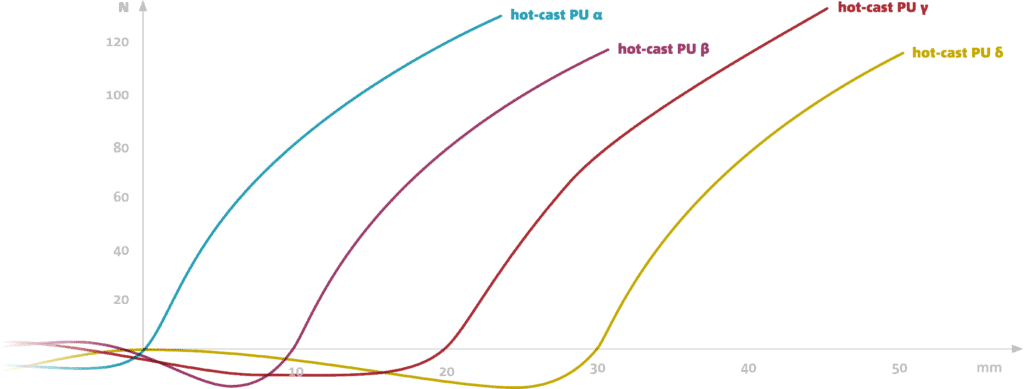

outstanding ABRASION RESISTANCE

- The abrasion data are the key to successful projects related to the fatigue resistance

- SYNTHENE is testing all its elastomers inhouse with the Taber Abrasion Test over 1000 revolutions or more to provide reliable information on a material’s wear resistance

- Typical applications are sieve meshes for mining, pipeline rollers, snowplough blades etc.

Abrasion resistance

| Product name |

Shore Hardness |

MG/100U |

Density |

| hot-cast PU A |

93 A |

2,00 |

1,1 |

| hot-cast PU B |

93 A |

2,60 |

1,1 |

| hot-cast PU C |

77 D |

10,00 |

1,1 |

| hot-cast PU D |

85 A |

107,00 |

2,36 |

| hot-cast PU E |

90 A |

38,00 |

1,05 |

TABER 1000 Rev/H22 1 kg

ISO 9352

Documents

Video Clip about abrasion resistance

A short video clip showcasing SYNTHENE’s test procedures to ensure the required abrasion resistance.

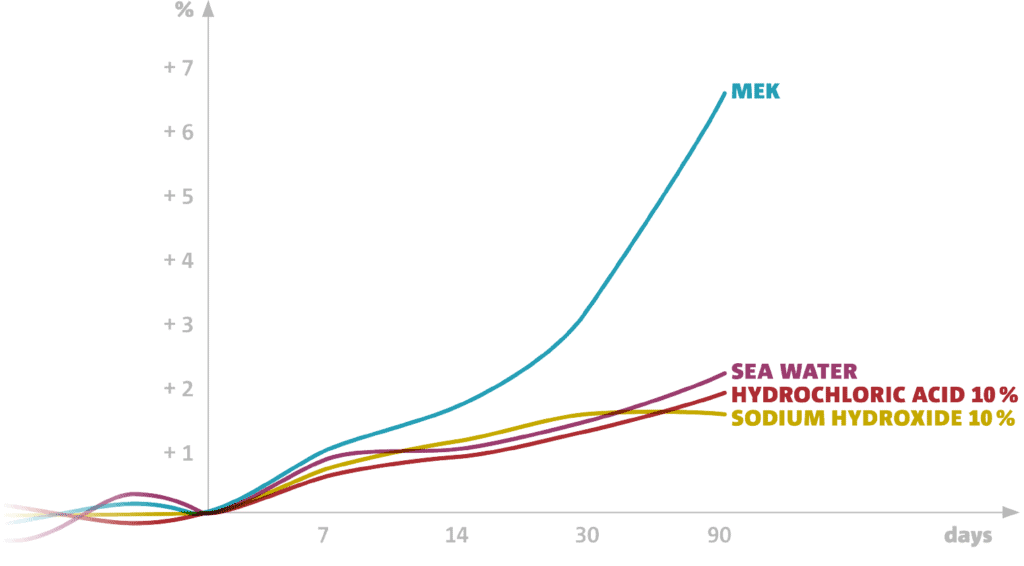

very high CHEMICAL RESISTANCE

- Polyurethane elastomers are versatile materials that encounter versatile environments

- Therefore SYNTHENE elastomers are tested over months in various chemical solutions

- Typical applications: oil & gas, water pipelines, heat exchangers, printing rollers etc.

Documents

Video Clip about chemical resistance

A short video clip showcasing SYNTHENE’s test procedures to ensure the required chemical resistance.