the UL94 Certified PRA794

- The most popular resin to meet demanding flame-retardancy requirements

- The PRA794 benefits from UL organisation accreditation as UL 94 V0 recognized material

- Yellow Card available: E523647

- Its self-extinguishing capabilities are necessary for most projects with an aero-spatial or electronic background and in public transportation

- Low aggressive isocyanate leads to extended life of the silicone moulds

Documents

TDS PRA794

Technical data sheet of the PRA794. All mechanical, thermal and fire resistance properties of the self-extinguishing prototyping resin PRA794.

- dielectric properties

- flame resistance

- thermal conductivity

- UL Yellow Card

Please contact us in order to get a copy of the test reports. We will happily provide them to you.

the FAR25 Licensed PRa730

- Flame resistance and self extinguishing properties required for aerospace projects like aircraft interiors

- Certified for the Federal Aviation Administration Regulations as a FAR25 material

- Limited aggressiveness to silicone moulds allows to cast up to 30 parts with a single mould

Documents

TDS PRA730

Technical data sheet of the PRA730. All mechanical and thermal properties of FAR25 prototyping resin PRA730.

Are these materials thermoplastic or thermoset materials?

These polymers are thermoset polyurethane resins, which means they cannot be processed through extrusion. Instead, they are supplied as two-component systems consisting of a polyol and an isocyanate. The components are mixed together in a vacuum casting machine and poured into a silicone mold. This molding process produces fully functional prototypes or small production runs with excellent strength and a high-quality surface finish.

Are these materials filled?

Yes. Our flame-retardant urethane resins are formulated with fillers to enhance their self-extinguishing properties.

While the presence of fillers generally impacts viscosity and stiffness, our products are designed to maximize flowability and maintain reliable physical properties for vacuum casting applications.

-

PRA794 → Mix viscosity: 1 100 mPa·s / Flexural modulus: 1 900 MPa (similar to a regular ABS thermoplastic).

-

PRA730 → Mix viscosity: 2 500 mPa·s / Flexural modulus: 2 100 MPa (like a rigid ABS plastic material).

For comparison, these stiffness levels are higher than Polypropylene and lower to the rigidity typically found in PA (polyamides), while still keeping excellent processability for vacuum casting.

Are these materials suitable for injection-molding?

We recommend to use the PRA730 and PRA794 for vacuum casting only, as detailed in the Technical Data Sheets of the materials.

For question about injection possibilities, please contact our Team.

Are the material thermally conductive?

The PRA794 has been tested by an independent laboratory regarding thermal conductivity. Please contact us to get more information about the test report.

How about the dielectric properties?

The CTI (Comparative Tracking Index) and the electric strength of the PRA794 urethane resin have been tested by an independent laboratory. For information about the results, our Team will be glad to support you.

Is this range resistant to chemical aggressions?

In the literature, this type of formulation is known to offer chemical resistance.

However, the actual performance depends on the specific environment and conditions of use. Factors such as solvents, oils, alkaline solutions, seawater, distilled water, or automotive fluids can have very different impacts on the material.

For these reasons, we strongly recommend that users perform compatibility tests in their own application to validate chemical resistance under real conditions.

As a reference, our PR7 SERIES has already demonstrated excellent resistance to chemical aggressions, making it suitable even for demanding engine environments.

Do the materials melt when exposed to flame?

Unlike thermoplastics, thermoset resins are less likely to melt when exposed to high temperatures. They retain their structural integrity much longer, even under fire conditions.

However, like any plastic, they will eventually deteriorate when exposed to flames. Thanks to their self-extinguishing properties, these resins significantly limit melting and dripping phenomena, offering improved safety compared to conventional thermoplastics.

The PRA794 has been tested according to UL94 standard, and the PRA730 according to the FAR25 standard, demonstrating their compliance with widely recognized fire-safety benchmarks.

How aggressive are the resins towards silicone molds?

One of the greatest strength of this range is to protect to tooling material as much as possible. Moulding fabrication process can be repeated multiple times without significant damage to the silicone-rubber. Of course, results may vary depending on the part geometry and the silicone brand, but based on customer feedback, it is common to achieve 30 or more castings from a single silicone mold.

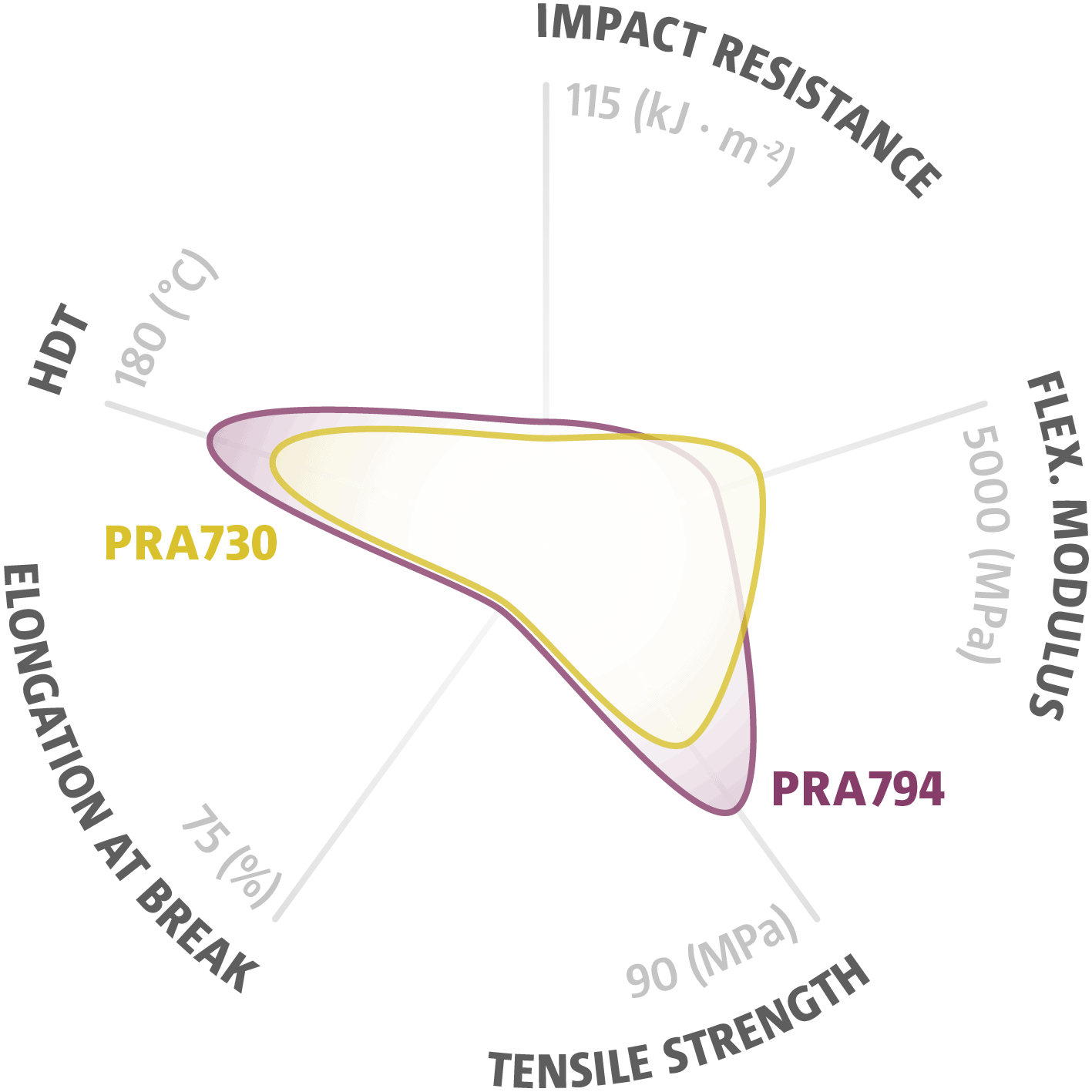

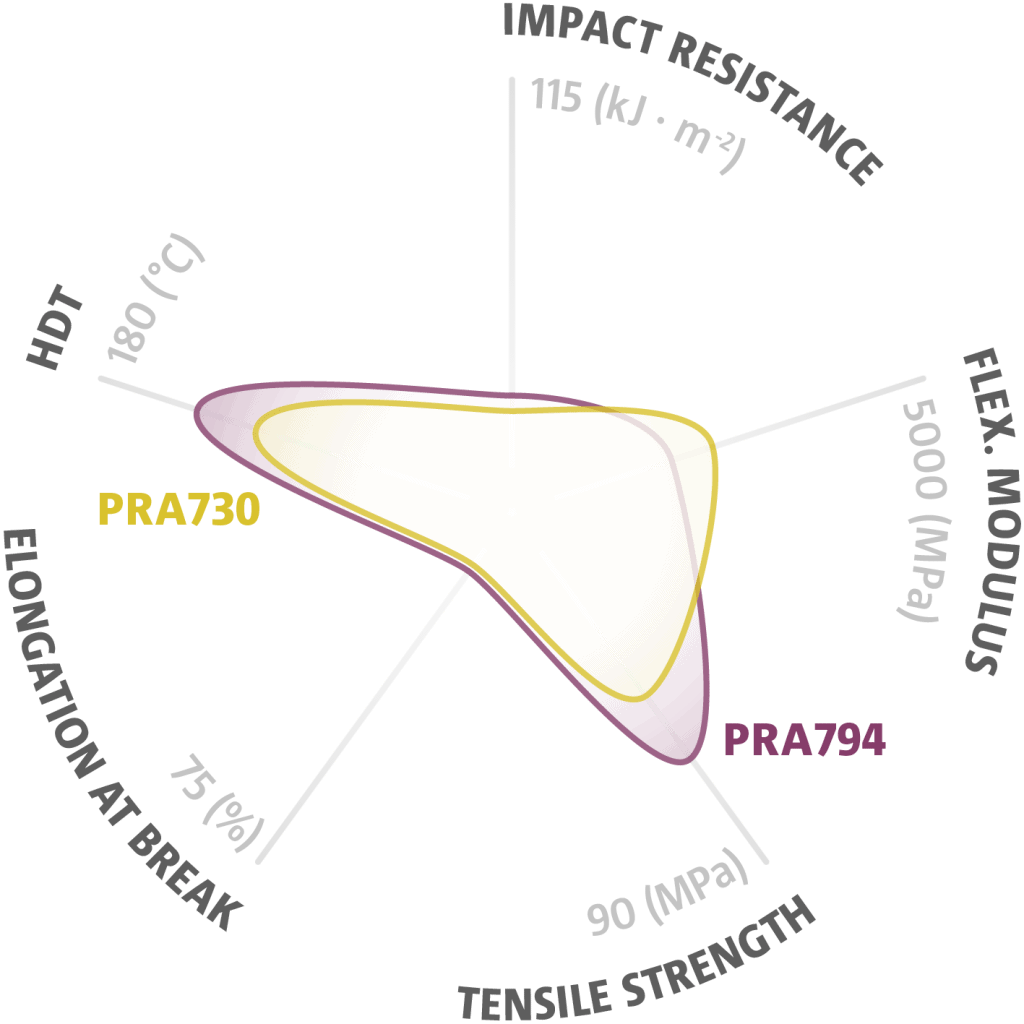

How mechanically strong are these vacuum casting resins?

These vacuum casting resins offer high mechanical strength and toughness, making them well-suited for demanding applications.

They are specifically designed to countertype ABS thermoplastics, providing comparable levels of flexural strength and tensile strength, while maintaining the ease of processing required for vacuum casting.

Can the materials withstand high temperatures?

Yes, these resins have been formulated to withstand warm temperatures. The PRA794 has a 130°C Heat Deflection Temperature (HDT) and the PRA730 reaches a >130 Glass Transition Temperature (Tg).

Can additives be used in the materials?

As the materials are already optimized for fire-resistance, we do not recommend to add any more filler to the formulas.

The addition of Pigments could also alter the flame retardancy of these products, so we recommend to keep them natural.

The PRA730 is dark grey, and the PRA794 has a dark brown colour. For materials that are as crystalline as Epoxy, we recommend you to check the Clear & UV-stable range. Some of these resins have been tests with the EN 60695-11-10A standard (HB).