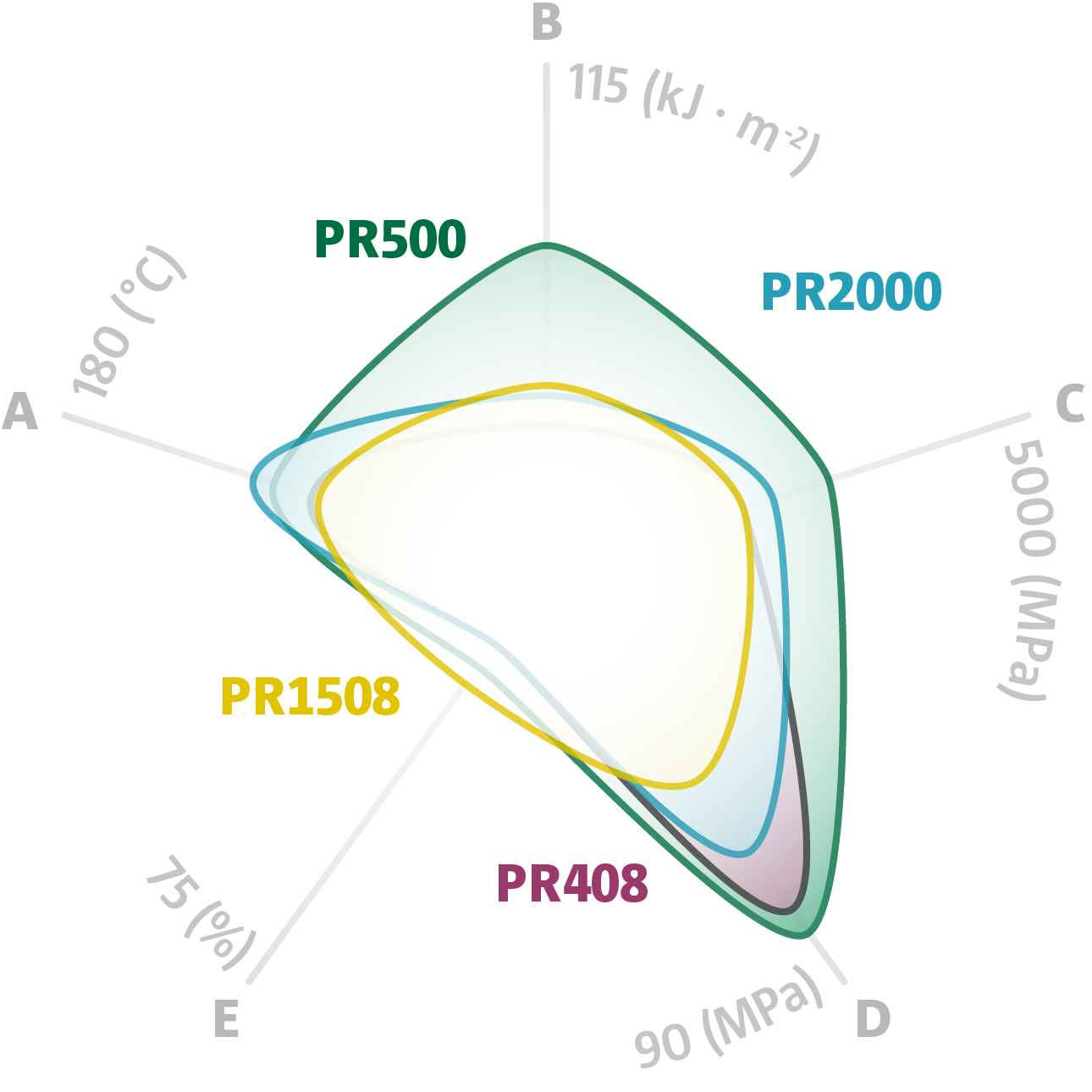

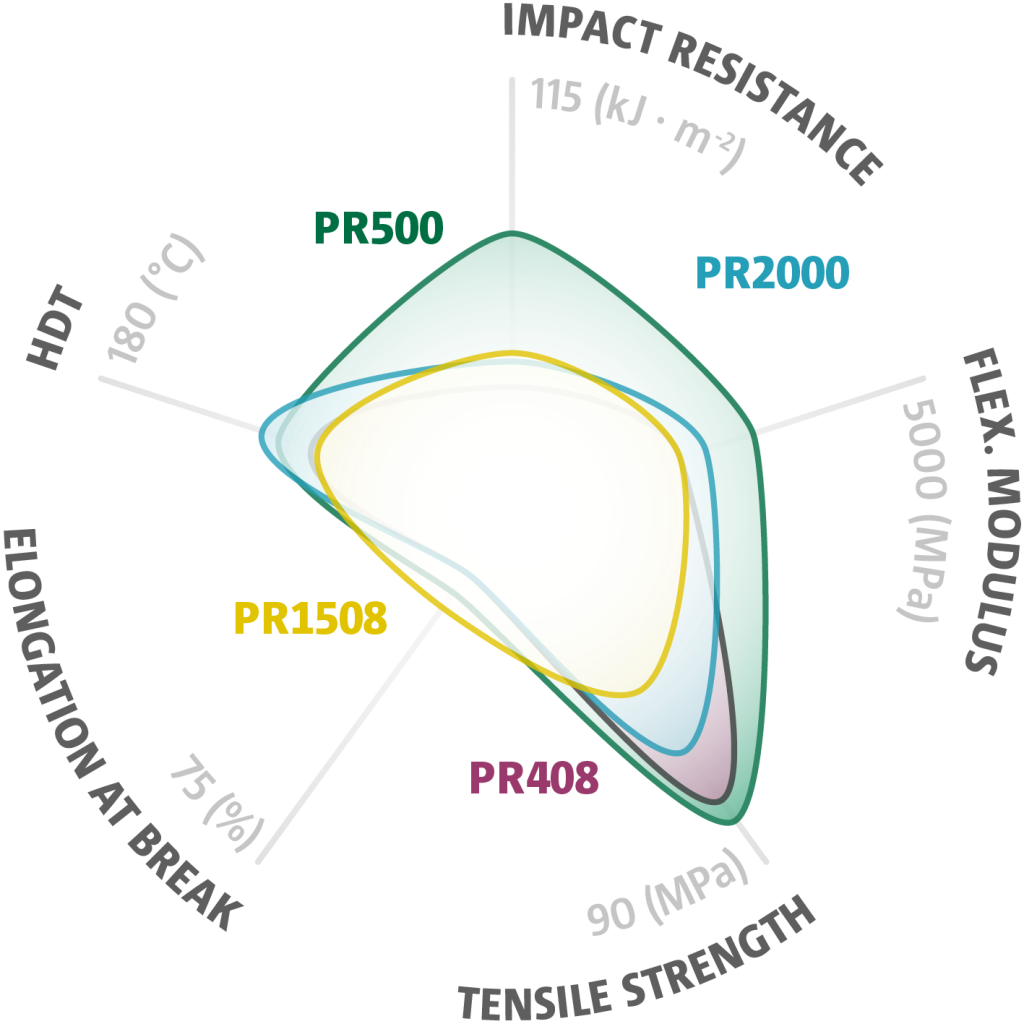

The Fast Demoulding PR500

- Very strong mechanical properties immediately after demoulding, no post-curing required

- Clear and colourable material

- High rigidity of 2600 MPa and up to 5600 MPa with the addition of the glass fibre filler SYNFILL G

- Possibility to increase the dimensional stability with the fibre glass filler SYNFILL G

Documents

TDS PR500

Technical data sheet of the PR500. All mechanical and thermal properties of the colourable and rigid prototyping resin PR500.

TDS PR500 + SYNFILL G

Technical data sheet of the PR500 with SYNFILL G. All mechanical and thermal properties of the colourable and rigid resin PR500, at different filler rates of added Synfill G.

- dielectric properties

- thermal conductivity

Please contact us in order to get a copy of the test reports. We will happily provide them to you.

What type of polymers are these resins?

These material are all thermoset polyurethane resins, formulated for the technology of vacuum casting. This technique is particularly relevant for prototyping or small series projects.

Thermoset resins are composed of 2 components: 1 polyol and 1 isocyanate. When mixed together in the vacuum casting machine, they react together with a cross-linking effect, resulting in a bonding of the chemical components. The obtained material is then highly durable and can withstand real application conditions. Their goal is to imitate themoplastic series materials like ABS and PA, including their mechanical properties; to get a complete idea of the final project.

The physical properties of a thermoset urethane and a thermoplastic are quite different, due to their chemical nature. For example, a thermoplastic melts when exposed to high temperatures, wheareas the chains of the thermoset polymer are bonded and the material is more likely to suffer from deformation. When cured, the mechanical properties of both materials are very close and it is interesting to use the vacuum casting technology in the prototyping phase.

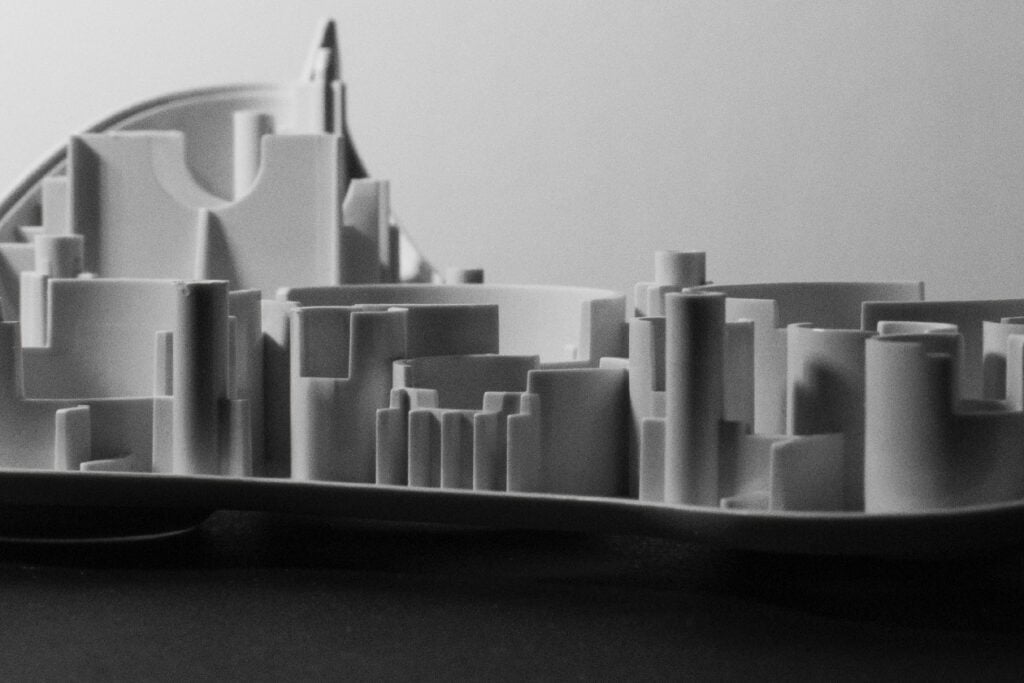

Why use the vacuum casting technology?

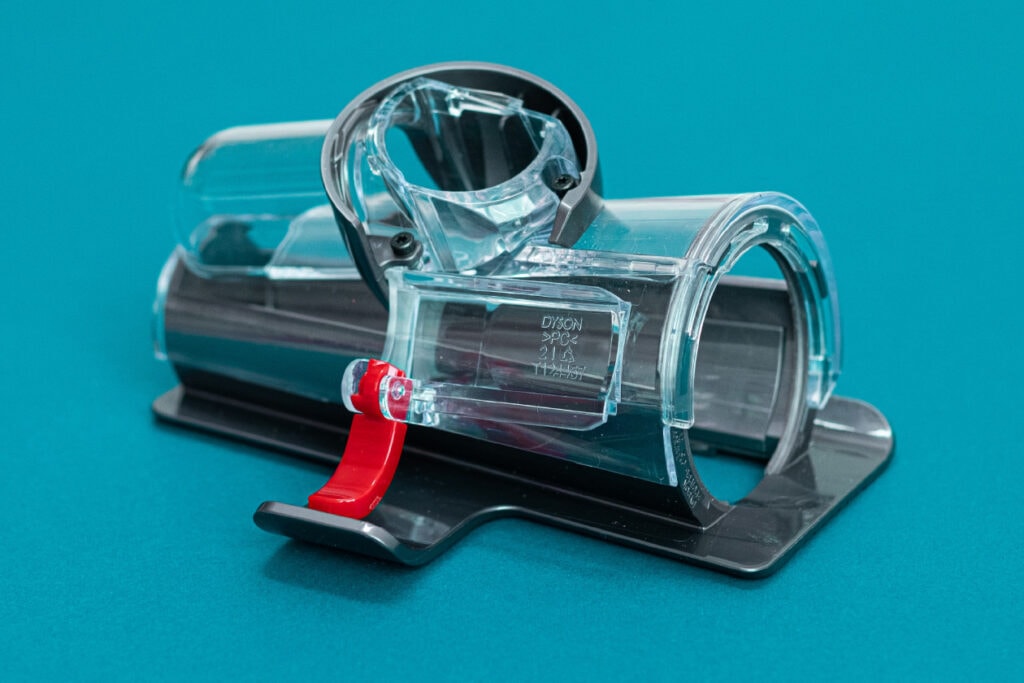

This technology allows one to create functional technical plastic parts, multiplying it into several pieces, without the use of pricey aluminium tooling. Vacuum casting is particularly interesting for the fabrication of prototype parts or shorts series up to 500 parts.

The use of vacuum aims to prevent the apparition of bubbles inside the resin, ensuring high strength and a nice looking polyurethane part.

What kind of mould should I use?

We recommend to use polyaddition silicone to create the mould. The use of a proper mould is critical for the quality of the final part, it is also important to use a good quality silicone-rubber to guarantee a certain amount of castings in one single mould.

Can I add pigments?

All these polymers are colourable. Though not 100% UV-stable, they all show a good stability when exposed to UV light. Synthene produces opaque pigments for basic colours : black, white, blue, yellow, green and red. Contact our Team or your local distributor to know more about these materials.

For other colours, we recommend to use solvent-based tints.

We invite the users to always pre-mix the colours with the polyol component before realising the mixture with the isocyanate

How can I increase the properties?

Synfill G glass fiber filler works as a reinforcement additive that increases the mechanical strength of the polymer, both in traction and in flexion.

The filler rate is adjusted depending on the requested properties: the more filler is added, the more rigid the material will be.

We recommend to always pre-mix the fiberglass filler in the isocyanate component before carrying out the mixing with the polyol.

Can these material withstand high temperatures?

The materials of this range are basic ABS-like resins for everyday jobs. Their goal is to simulate a regular thermoplastic to make functional parts. Therefore their HDT is between 70°C and 101°C.

For higher temperature resistance, we recommend to favour the PR7 SERIES range.

Are they adapted to injection-moulding?

For injection purposes, the PR7 SERIES materials like PR700 show more efficiency.

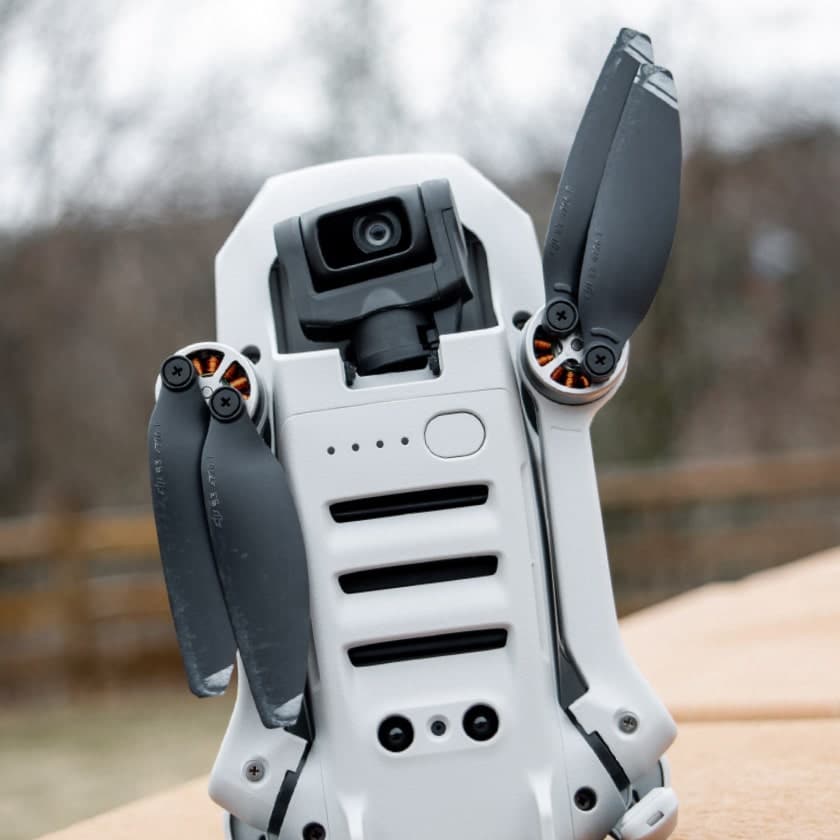

What fields of activity are these products for?

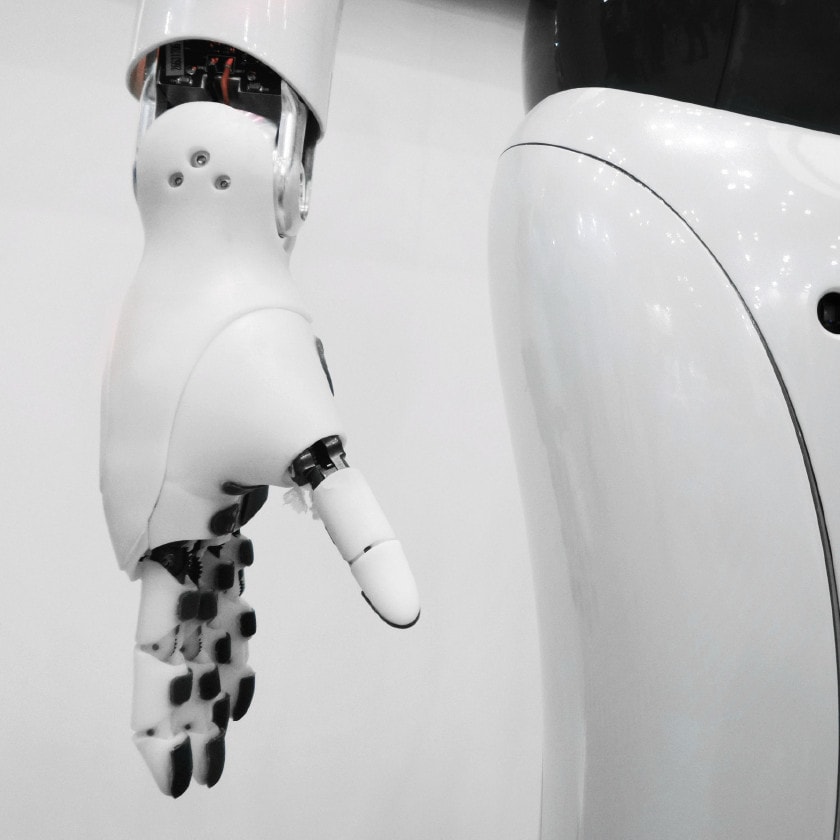

As they simulate regular ABS and PA thermoplastics, these PU resins find applications across multiple fields. Medical, smart goods, aerospace, automotive, household products, consumer electronics…

Are these products rigid or soft resins?

All these vacuum casting resins are rigid products. For a more elastic product, we recommend you to check our range of elastomers for rapid prototyping.

Should the materials be post-cured?

The PR408 and PR1508 don’t require a post-curing. These thermosetting plastics are already stiff enough to be taken out of the mold after 2h at 70°C.

Although it is also the case for PR2000 and PR500, we recommend to realise a post-curing in an oven to enhance the properties of these resins. Even though the material is not brittle after demoulding, it is a good option to cure the material in the mold or in a shape-holder a little longer – as described in the technical data sheet. This extra curing step will bring more toughness to the material.

Is this range similar to Polypropylene?

These materials similar to ABS, PA, filled ABS or filled PA.

For nylon-like product, we recommend to combine the PR500 with Synfill G glass fiber filler.

The glass fiber filler will give more stiffness to the material as it increases the flexural modulus.

Is this range similar to Polyethylene?

This range is made to countertype rigid ABS-like basic parts.

For the moulding of semi-flexible products such as PP-like materials or elastomers, we recommend to check the PR777, PR740 and HPR65 products.

How about the chemical resistance of these materials?

This range is thermoset and therefore remains quite stable regarding the absorption of water or other chemical agents. Nonetheless, these resins haven’t been formulated to be particularly chemically resistant, and tests have not been conducted for this parameter.

Are these materials adapted to a composite application?

This range of thermoset resins is dedicated to the moulding of parts in silicone moulds, with the technology of vacuum casting.

Are they adapted to injection-moulding?

Due to their “milky time” reaction during the mixing step, we recommend to use these products on only in vacuum casting machine, or hand casting if stated in the Technical Data Sheet.

Are these product electrically conductive?

Dielectric properties and comparative tracking index (CTI) have been tested for the PR500 material. Contact us for more information.