Crystal-CLEAR & UV-STABLE

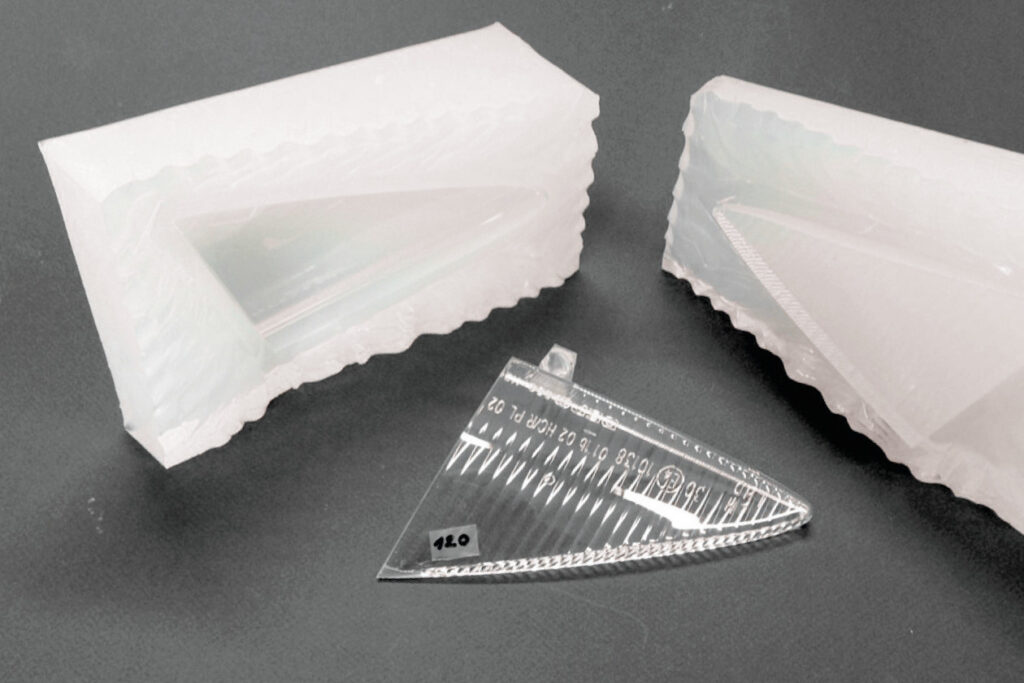

- Adapted solutions from thin PRC1810 to mass CRISTAL HRI 35 casting

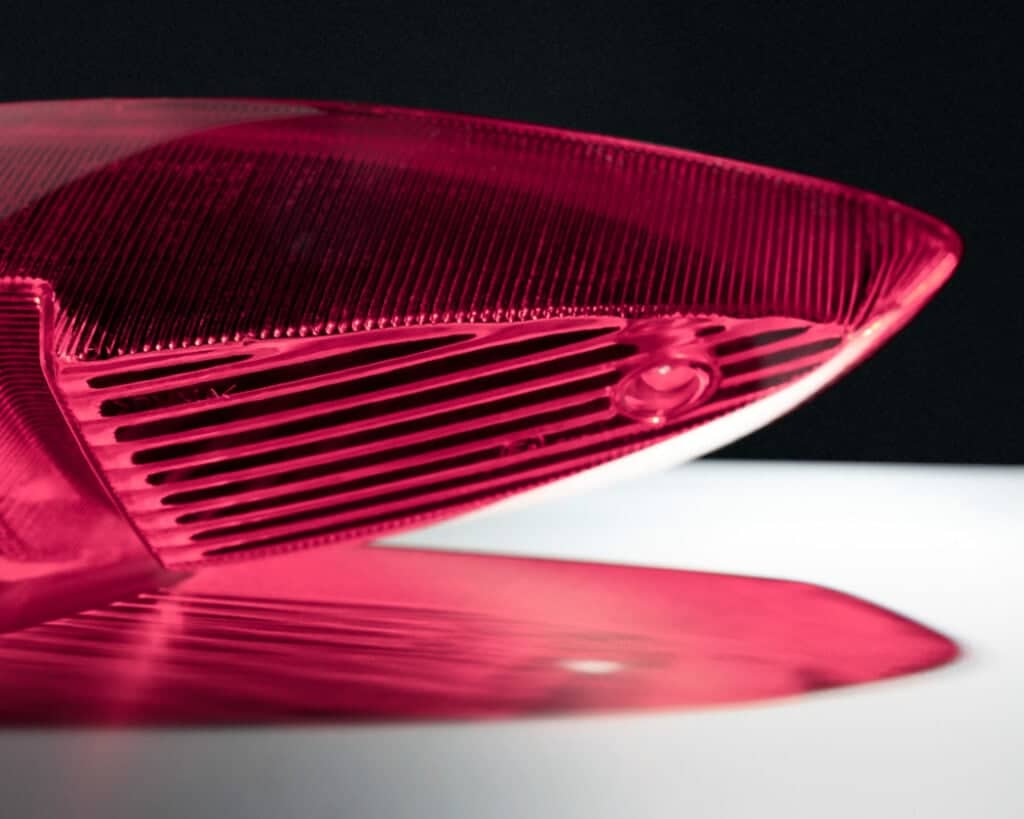

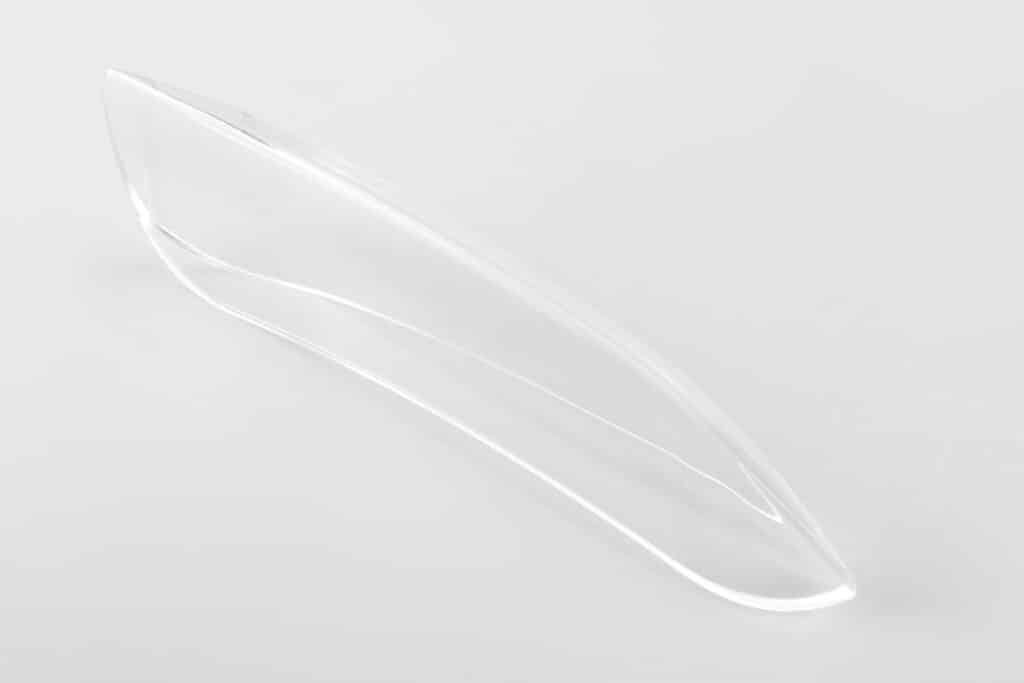

- A stunning combination of thermal, mechanical and optical properties for projects like automotive headlamps or perfume bottles

- Extreme UV-resistance even in outdoor conditions

- Possibility to adapt the level of diffusion with the light diffusing additive PP0420 for lighting design

Since the 1970s SYNTHENE has built a lot of expertise and know-how formulating transparent resins with high UV‑stability.

In Accordance With

EC Regulation 1907/ 2006

Directive EU 2011/ 65, 2015/ 863 & 2017/ 2102

2000/ 53/ EC

2002/ 96/ EC

2000/ 11/ EC

IMDS (mdsystem.com)

Documents

TDS diffusing additive PP0420

Technical data sheet of the PP0420. All physical properties and application process of the light diffusing additive.